Best Rotary Hammer with Easy Replacement of Carbon Brush

Model: DG-2-2804

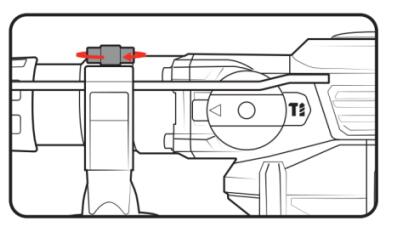

***Efficient Maintenance-quickly replace worn brushes without specialized tools

***Cost-Effective -save money and time by enabling users to replace carbon brushes themselves.

***User-Friendly-allows users to take brush replacements quickly and keep their tools in top condition with minimal effort.

Get Latest Price

Specification

Descriptions

PRODUCT OVERVIEW

The Best Rotary Hammer with External carbon brushes allows the user to check usage at any time and saves time and effort in replacing carbon brushes.

The Best Rotary Hammer with External carbon brushes allows the user to check usage at any time and saves time and effort in replacing carbon brushes.

Powerful 820W motor and 3.0J of impact energy for fast hammer drilling in concrete (up to 28mm diameter).

Powerful 820W motor and 3.0J of impact energy for fast hammer drilling in concrete (up to 28mm diameter).

The SDS-plus bit system provides tool-free bit changes with automatic bit locking, dust protection and maximum impact energy transfer.

The SDS-plus bit system provides tool-free bit changes with automatic bit locking, dust protection and maximum impact energy transfer.

Lightweight for operator comfort

Lightweight for operator comfort

Rich Function with simple operation for corded rotary hammer.

Rich Function with simple operation for corded rotary hammer.

Lock-on button for continuous use.

Lock-on button for continuous use.

Non-slip handle provides a secure and comfortable grip, 360 degree swivel of auxiliary handle with textured grip offers user maximum control and comfort.

Non-slip handle provides a secure and comfortable grip, 360 degree swivel of auxiliary handle with textured grip offers user maximum control and comfort.

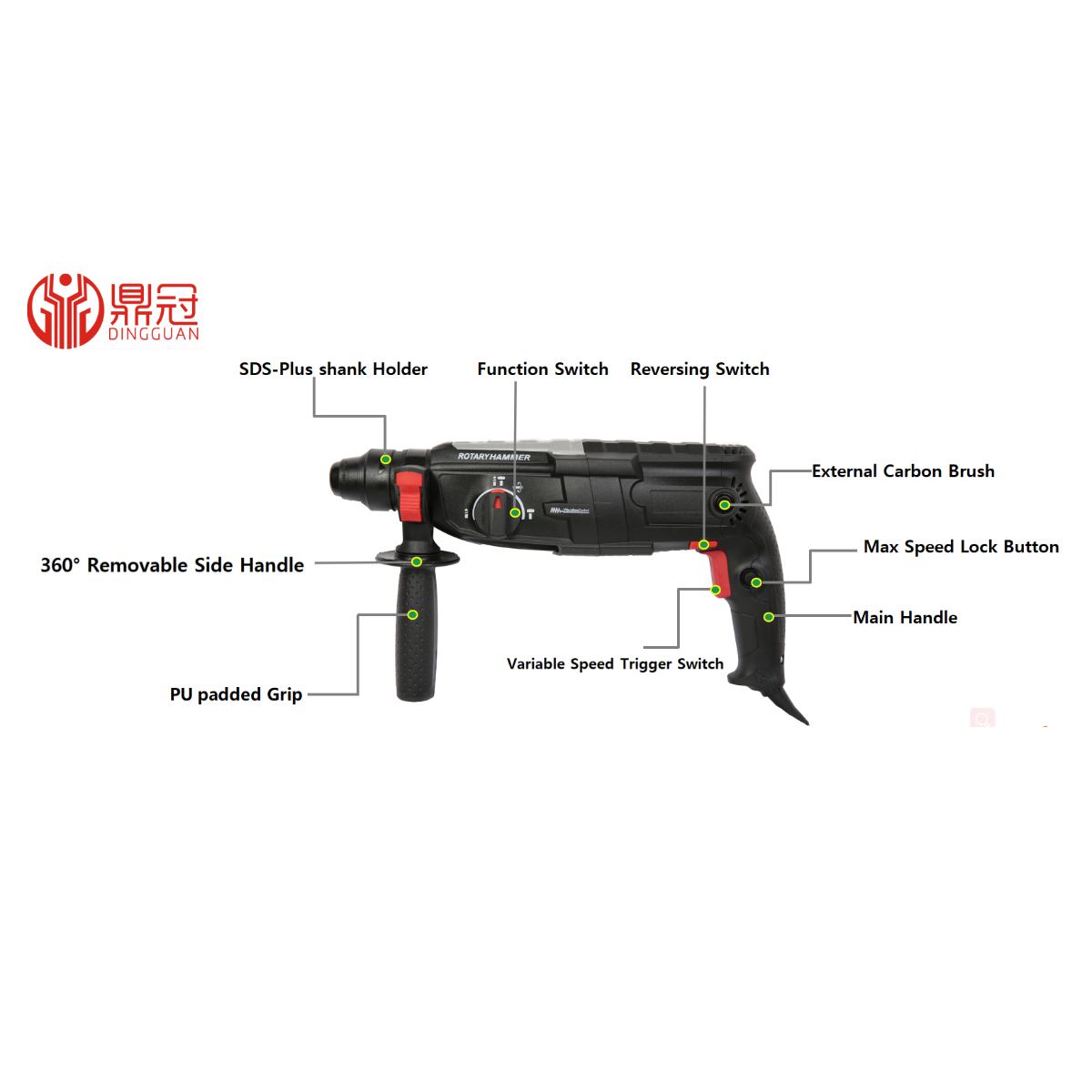

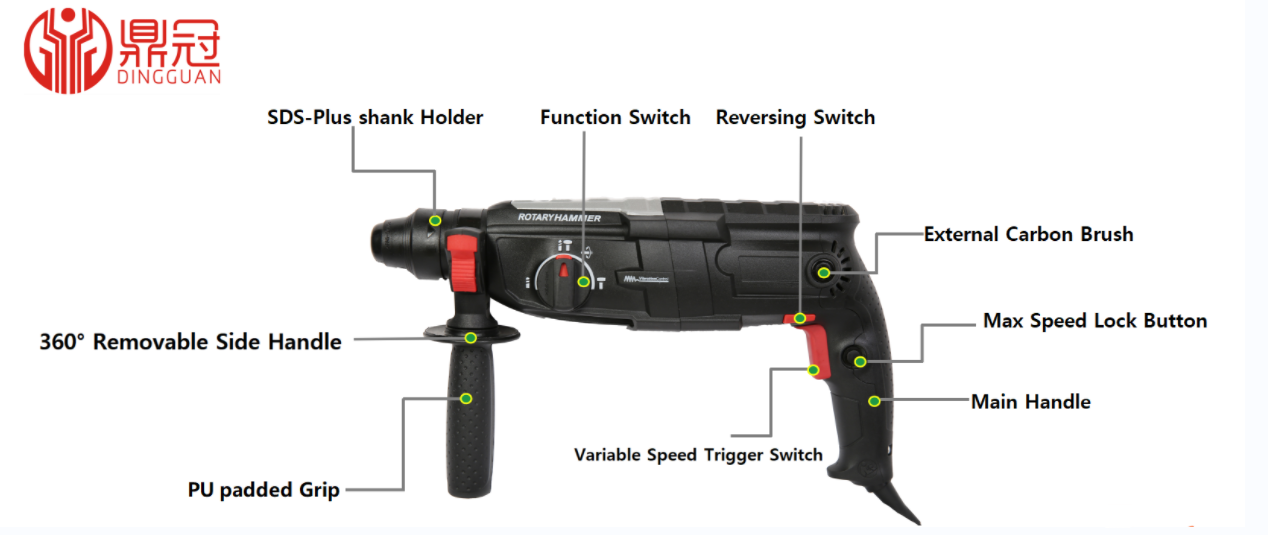

MAIN COMPONENTS

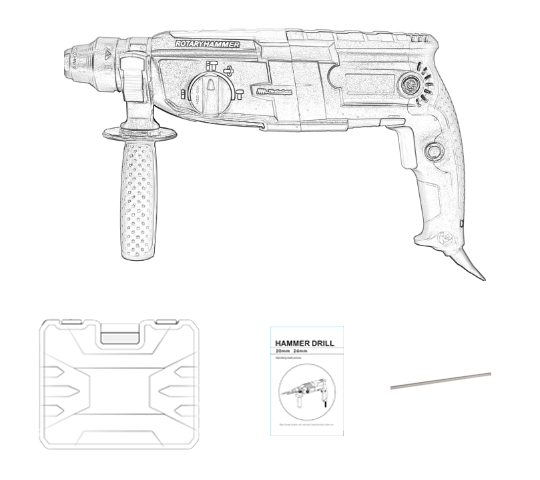

STANDARD PACKING

• Best Rotary Hammer* 1

• Attached auxiliary handle* 1

• Metal depth gauge* 1

• Carrying case* 1

• Manual Instruction* 1

VERSATILE FUNCTIONS

• Drilling Mode for drilling into wood or metals

• Hammer drilling Mode for drilling into concrete,cement,rock or stone ![]()

• Chiseling Mode for removing tiles, walls or chiseling cable ducts

• Chisel position adjustment for

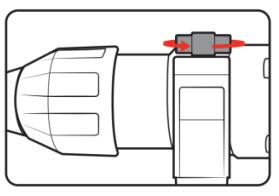

MAINTENANCE

The best rotary hammer with carbon brushes outside was properly lubricated before leaving the factory. In from two to six months, depending upon use, take or send your SDS Rotary Hammer to an authorized service center for a complete cleaning, inspection and lubrication. The rotary hammer drill used constantly on production jobs will need relubrication more often. Also, tools “out of service” for long periods should be relubricated before being put back to work.

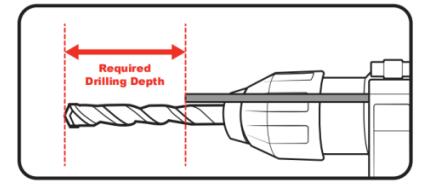

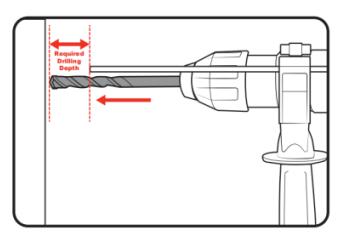

DEPTH GAUGE USING

The depth rod allows you to drill to a predetermined depth.

1) Loosen the depth rod securing nut,then insert the rod.

2) Adjust the depth rod so that the drill bit extends beyond the end of the depth rod to the required drilling depth.

3) Tighten the depth rod securing nut to lock the depth rod into place.

4) Then drill as normal until the depth rod touches the surface of the workpiece.

TROUBLESHOOTING GUIDE

| PROBLEMS | CAUSES | REMEDY |

| Motor doesn't start | ① The conductor wire, connecting motor and on/off switch may broken. |

Replace the conductor wire. |

| ② Carbon brushes worn out. |

Have to replace carbon brushes. |

|

| ③ Unsure |

Return to an authorized service agent for diagnosis. |

The Leading Manufacturer of SDS Rotary Hammer Drill

Related Products

FAQs

Frequent Asked Questions for Placing an Order

Q: What quality do you supply ?

Q: What's the minimun quantity of order do your factory take?

Q: How long will it take for order production.

Q: What's kind of warranty do I have?

Get In Touch With Us

Committed to providing Reliable, Powerful and Extrme Long service life conceret tool for mansons, carpenters, remodelers,electricians, maintenance crews in various projects. Such as interior renovation, construction or road construction.

Tel: +86 15355628697

Tel: +86 15355628697

Email: alva.pan@tzboneng.com

Email: alva.pan@tzboneng.com

Add: NO.4 Fengjiang Rd,Luqiao,Taizhou City, Zhejiang, China

(Z.P. 318000))

Add: NO.4 Fengjiang Rd,Luqiao,Taizhou City, Zhejiang, China

(Z.P. 318000))

Inquiry Now

Please give us a message for your enquiry order or advice.

Send Message